Under Voltage Lockout Circuit

Motivation

One of my research assignments while in the TENNLab Neuromorphic Research Group, GRANT, was a robot that autonomously roamed around a room to find a target while avoiding obstacles in its path. Operating the robot’s motors and external sensors required a large amount of current on two separate circuits. Because of this, the LiPo batteries used to power the robot could easily drain past an acceptable level over several hours of testing. To ensure that these batteries never drained low enough to cause permanent damage or decrease the lifespan of the batteries, I designed an undervoltage lockout circuit (UVLO). The UVLO was then placed onto a PCB with an accompanying fuse for overcurrent protection and a voltage regulator so that an appropriate voltage level was output.

Objectives

- The cutoff voltage should be 6.8 V for our 2 cell LiPo battery.

- A 300-500 mV hysteresis should be present to prevent voltage bouncing.

- The circuit should draw minimal power without being too expensive.

- The PMOS path should be able to sustain at least 3 A of continuous current.

Design

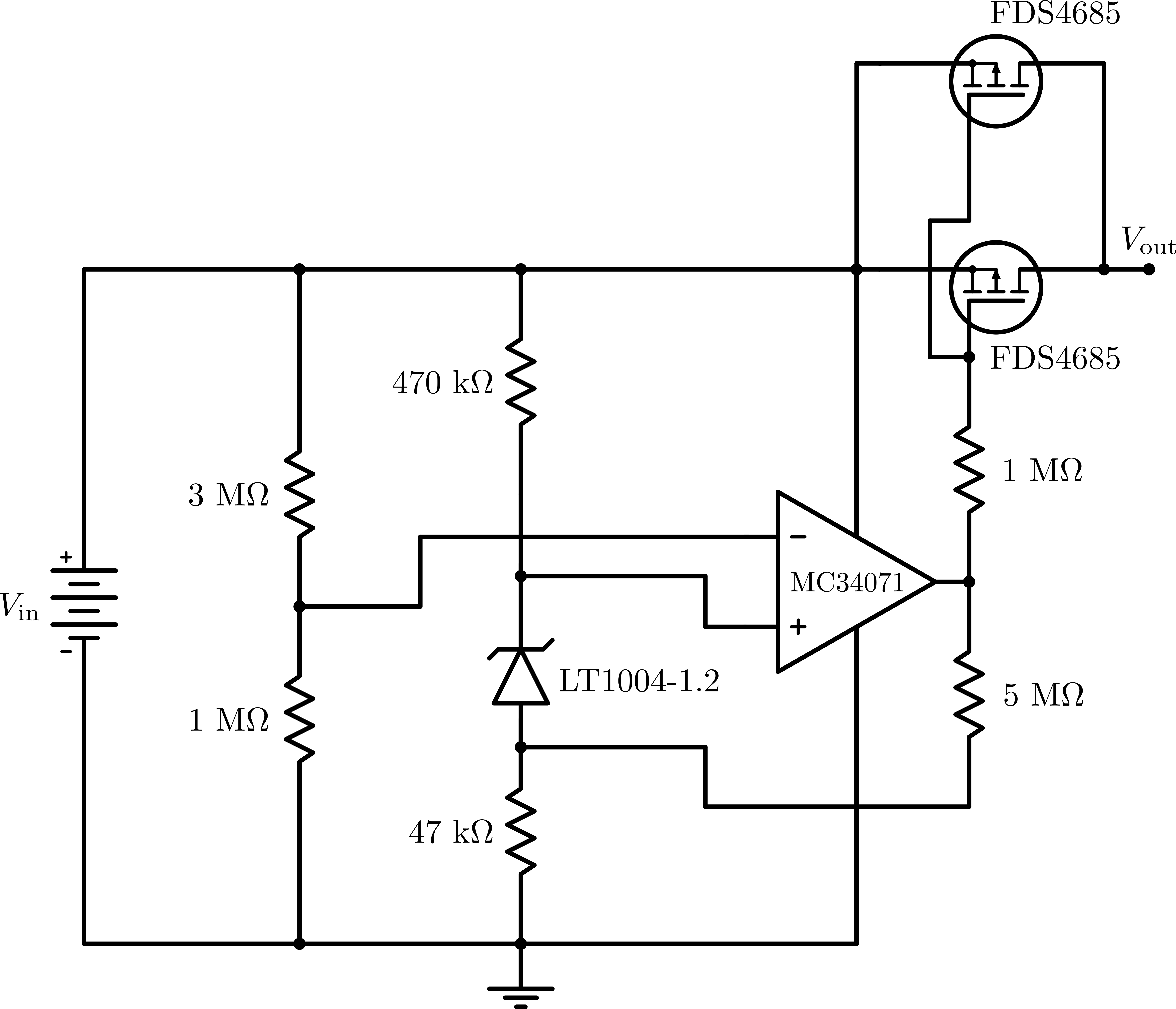

The basic circuit configuration is shown in the figure above. This design is based off of a Li-Ion battery protection circuit posted by Analog Devices. Their description of the basic operation of the circuit is sound, but can be a little confusing, so I will reiterate that here as well as breakdown how the components were selected for this implementation.

Functional Description

The overall circuit is a operational amplifier used as a comparator to control the switching of a p-channel MOSFET. Resistors and are used to provide a divided input voltage to the negative terminal of op-amp. This voltage should remain higher than the voltage at the positive terminal of the op-amp when the battery input voltage is within acceptable levels. The voltage at the positive terminal of the op-amp drops at a slower rate than the voltage at the negative terminal of the op-amp as the battery discharges. This is due to the added zener diode voltage reference. When the voltage at the negative terminal of the op-amp drops lower than the voltage at the positive terminal, the output of the op-amp swings high and turns off the PMOS switch. The addition of resistor facilitates hysteresis in the switching operation. This works by injecting a small amount of feedback current into the node connected to the cathode of the zener diode when the battery voltage is low. This extra current lifts the voltage at the positive terminal of the op-amp making it such that the voltage at the negative terminal must increase to a higher level before reaching the critical crossover point and closing the PMOS switch.

Component Selection

As mentioned in the objectives of the project, the circuit needed to be reasonably cheap and easy to make while handling a high current output. Luckily, a similar project left us with several FDS4685 p-channel MOSFETs that are rated to handle more than 3 A of continuous current and would cost us nothing. As for the op-amp, several MC34071 general purpose op-amps were on hand and were used. The zener diode choice needed more thought, as any that we already had required too much current to operate properly. With research into micropower zener voltage references, the LT1004 1.2 V variant was chosen. This zener diode only requires 10 A of current to operate properly and provides a 1.2 V reference.

With those main components decided, all that remains is to determine resistor values so that this circuit operates properly for our battery selection. The battery used is a 2 cell 7.4 V LiPo. Each cell should reach a voltage of no lower than 3.4 V or else risk permanent degradation. So, the cutoff voltage is set to be 6.8 V. The selection of and is mostly arbitrary, but since very little current should flow through any branches besides the main path through the PMOS, they are selected to be quite high with a value of 3 M and 1 M respectively. This places the voltage at the negative terminal of the op-amp to be around 1.7 V when the undervoltage cutoff point is reached.

Some simple voltage division can be applied to the branch of the circuit containing resistors and so that they are sized where the voltage at the positive terminal of the op-amp matches the voltage at the negative terminal once this critical point is met. By doing this, the crossover point is set to occur when the battery voltage reaches 6.8 V. The math yields a value of 510 k and 50 k for resistors to respectively, also considering the 10 A current flow that the zener diode imposes. We simply round this to more standard values and set them to 470 k and 47 k respectively.

Finally, resistor can be set to a simple 1 M as it is just in place to reduce noise in the switching of the PMOS. The hysteresis resistor is then sized so that the current injected causes a voltage increase of 0.3-0.5 V at the feedback node when the output of the op-amp swings high. Sizing this proved to be a little less trivial, so simulation was used and verified physically. The final value chosen was 5 M.

Results

When combined with a fuse for overcurrent protection and a voltage regulator at the output, this circuit worked great for our robot. No on/off bouncing occurred when the battery voltage ran low thanks to hysteresis, and the voltage switching point was quite close to what was designed for. One final adjustment that was made was the addition of a parallel PMOS to limit the current through each one. This was added because of just how hot the PMOS got when the motors of the robot stalled. A final circuit diagram can be seen below.